In the ever-evolving field of industrial engineering, the integration of advanced technologies plays a pivotal role in shaping the future of manufacturing and production processes. Among these advancements, the convergence of robotics and nanotechnology stands out as a transformative force. By understanding what industrial engineering is and how these cutting-edge innovations are revolutionizing the industry, we can appreciate the potential of robotics enhanced by nanotechnology. For those pursuing an industrial engineering degree or considering the industrial engineering major, the future promises exciting developments driven by these technologies. If you’re looking for more inspiration on presenting these concepts, consider exploring DoMyEssay PowerPoint presentation ideas for students.

The Role of Robotics in Industrial Engineering

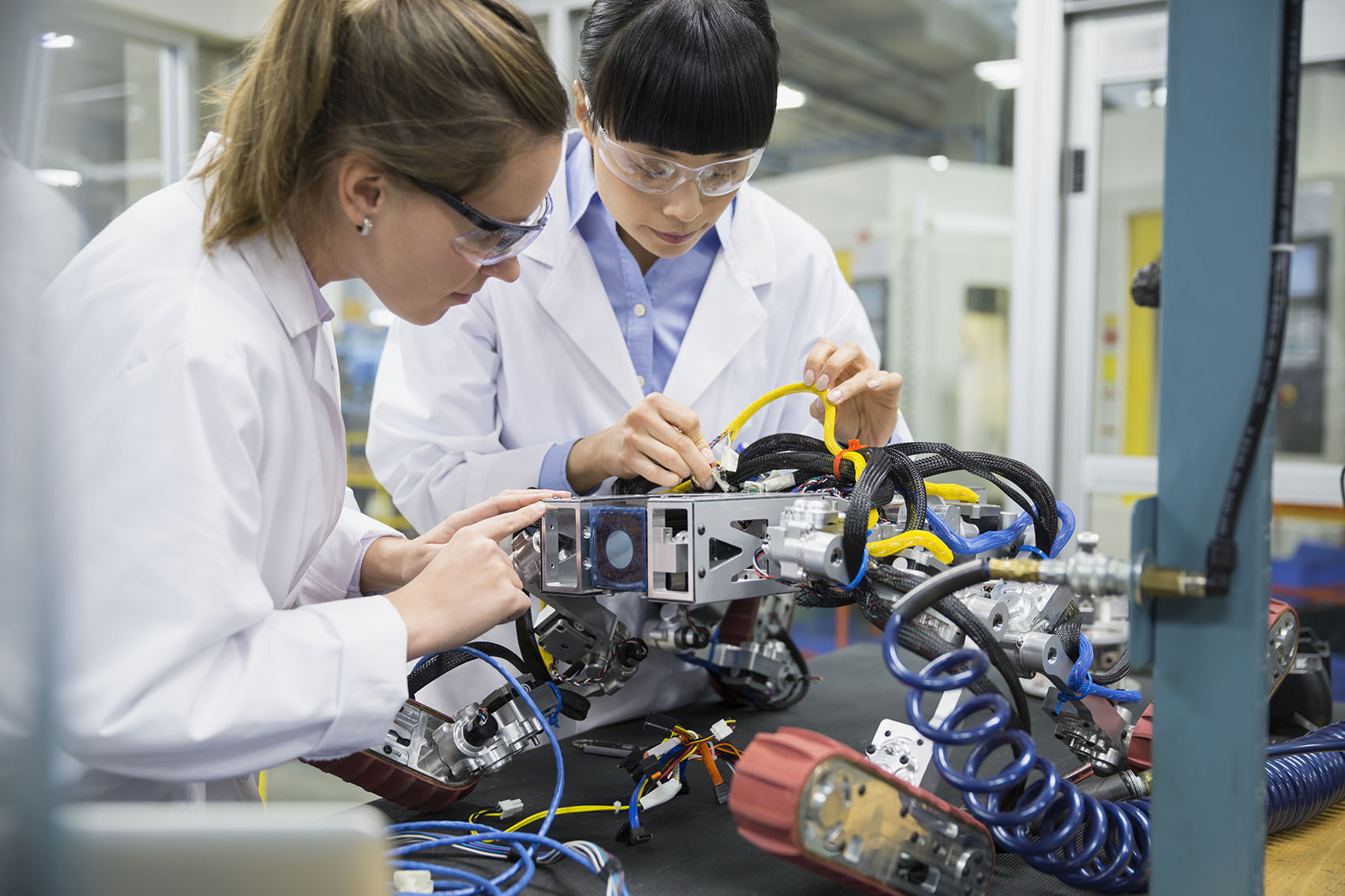

Robotics has long been a cornerstone of industrial engineering, driving automation and enhancing productivity across various sectors. By automating repetitive and labor-intensive tasks, robots have enabled companies to achieve greater efficiency, accuracy, and cost savings. In the context of industrial engineering, robotics is not just about machinery; it encompasses the integration of advanced systems that work harmoniously with human operators to optimize processes and outcomes.

Enhancing Efficiency and Precision

In industrial engineering, the primary goal is to streamline operations and improve efficiency. Robots excel in this area by performing tasks with a level of precision and consistency that is unattainable by human workers. From assembly lines in automotive manufacturing to packaging in food processing, robots handle complex tasks with remarkable speed and accuracy. This not only boosts productivity but also ensures high-quality output with minimal errors.

Safety and Risk Mitigation

Another significant advantage of robotics in industrial engineering is the enhancement of workplace safety. Robots can operate in hazardous environments, handling dangerous materials and performing tasks that would pose a risk to human workers. This reduces the incidence of workplace accidents and ensures compliance with safety regulations. For students pursuing an industrial engineering degree, understanding the role of robotics in safety is a critical component of their education.

Flexibility and Adaptability

Modern industrial robots are designed to be highly adaptable, capable of being reprogrammed for different tasks and processes. This flexibility is particularly valuable in industries where production lines need to be reconfigured frequently to accommodate changing product designs or market demands. As such, robotics plays a vital role in maintaining the agility and responsiveness of industrial operations.

Nanotechnology: A Game Changer in Robotics

Nanotechnology, the manipulation of matter on an atomic and molecular scale, has emerged as a revolutionary force in various fields, including industrial engineering. When applied to robotics, nanotechnology offers the potential to enhance capabilities, improve efficiency, and create new functionalities that were previously unimaginable.

Enhancing Material Properties

One of the most significant impacts of nanotechnology on robotics is the enhancement of material properties. By incorporating nanoparticles into traditional materials, engineers can develop stronger, lighter, and more durable components for robotic systems. For instance, nanocomposites can improve the wear resistance and thermal stability of robotic joints, leading to longer-lasting and more reliable robots. This is particularly important for industrial and systems engineering, where the durability and reliability of equipment are critical.

Miniaturization and Precision

Nanotechnology also enables the miniaturization of robotic components, allowing for the development of micro and nanoscale robots. These tiny robots can perform tasks with unparalleled precision, such as manipulating individual cells in medical applications or assembling microscopic structures in manufacturing. The ability to work at such a small scale opens up new possibilities for industrial processes, making them more efficient and precise. Students at the best industrial engineering schools are increasingly exposed to these cutting-edge advancements, preparing them for the future of the field.

Improved Sensors and Actuators

Nanotechnology enhances the performance of sensors and actuators used in robotics. Nanosensors can detect minute changes in the environment, providing robots with highly sensitive feedback that improves their responsiveness and accuracy. Similarly, nano actuators can enable more precise movements and control, allowing robots to perform delicate tasks with greater finesse. This level of precision is essential for complex industrial applications, from semiconductor manufacturing to pharmaceuticals.

Energy Efficiency and Power Management

Energy efficiency is a critical consideration in robotics, especially for mobile and autonomous systems. Nanotechnology can contribute to the development of more efficient energy storage and power management solutions. For example, nanoscale batteries and supercapacitors can provide higher energy densities and faster charging times, ensuring that robots can operate for longer periods without interruption. This advancement is crucial for industrial engineering major students who are exploring sustainable and efficient engineering solutions.

Applications and Future Trends in Industrial Engineering

The fusion of robotics and nanotechnology is paving the way for innovative applications and future trends in industrial engineering. As these technologies continue to evolve, they will significantly impact various sectors, driving advancements and creating new opportunities for efficiency and productivity.

Smart Manufacturing

Smart manufacturing, also known as Industry 4.0, leverages advanced technologies such as robotics, nanotechnology, and the Internet of Things (IoT) to create highly automated and intelligent production environments. In this context, nanotechnology enhances the capabilities of robotic systems, enabling them to perform complex tasks with greater precision and flexibility. For example, nanoscale sensors can be embedded in production lines to monitor processes in real time, ensuring optimal performance and reducing downtime. Students studying industrial engineering at top institutions are being trained to design and manage these smart manufacturing systems, preparing them for future industry demands.

Medical and Pharmaceutical Manufacturing

In the medical and pharmaceutical industries, the precision and accuracy provided by nanotechnology-enhanced robotics are invaluable. Nanoscale robots can be used for tasks such as drug delivery, where they can navigate through the human body to deliver medications directly to targeted cells. In pharmaceutical manufacturing, nanotechnology can improve the production and quality control of drugs, ensuring they meet strict regulatory standards. Industrial and systems engineering professionals are increasingly collaborating with medical researchers to develop these advanced robotic solutions.

Aerospace and Automotive Industries

The aerospace and automotive industries are benefiting from the integration of nanotechnology and robotics. Nanomaterials can significantly reduce the weight of aircraft and vehicles, improving fuel efficiency and performance. Additionally, nanotechnology enables the creation of highly sensitive sensors that can monitor structural integrity and detect potential issues before they become critical. Robotics plays a crucial role in assembling and maintaining these advanced transportation systems, and engineers with an industrial engineering degree are at the forefront of these innovations.

Here is how Toyota is innovating in manufacturing through robotics, AI, and big data:

Energy Sector

The energy sector is another area where nanotechnology-enhanced robotics is making a significant impact. For instance, nanorobots can be used to inspect and maintain oil pipelines, reducing the risk of leaks and environmental damage. In renewable energy, nanotechnology can improve the efficiency of solar panels and wind turbines, while robotics can automate their installation and maintenance. These advancements align with the goals of industrial and systems engineering to create sustainable and efficient energy solutions.

Future Trends: Autonomous and Collaborative Robots

Looking ahead, the future of robotics in industrial engineering will likely see an increased focus on autonomous and collaborative robots. Autonomous robots, equipped with advanced AI and nanotechnology, will be capable of performing tasks with minimal human intervention, enhancing productivity and reducing labor costs. Collaborative robots, or cobots, will work alongside human operators, providing assistance and augmenting their capabilities. These trends will require industrial engineering majors to develop skills in AI, machine learning, and human-robot interaction, ensuring they are well-equipped for the future workforce.

Educational Pathways and Career Opportunities

As the integration of robotics and nanotechnology continues to transform industrial engineering, educational pathways and career opportunities in this field are expanding. Aspiring engineers must equip themselves with the necessary skills and knowledge to thrive in this rapidly evolving landscape.

Pursuing an Industrial Engineering Degree

For those interested in exploring the intersection of robotics and nanotechnology, pursuing an industrial engineering degree is a critical first step. These programs offer a comprehensive education in designing, optimizing, and managing complex systems, providing students with a strong foundation in both theoretical and practical aspects of the field. Coursework typically includes subjects such as systems engineering, manufacturing processes, operations research, and robotics.

Specializations and Advanced Studies

As the demand for expertise in nanotechnology and robotics grows, many institutions offer specialized courses and advanced degrees in these areas. Students can choose to focus on nanotechnology applications in industrial engineering, gaining in-depth knowledge of nanomaterials, nanosensors, and nano actuators. Similarly, advanced studies in robotics can cover topics such as autonomous systems, artificial intelligence, and human-robot interaction. For those considering further specialization, combining these areas can provide a competitive edge in the job market.

Top Institutions for Industrial Engineering

Several of the best industrial engineering schools offer robust programs that integrate robotics and nanotechnology into their curricula. These institutions provide access to state-of-the-art laboratories, research opportunities, and industry partnerships. Some of the top schools known for their industrial engineering programs include MIT, Stanford University, and Georgia Institute of Technology. Graduates from these institutions are well-prepared to lead the way in implementing advanced technologies in industrial settings.

Career Opportunities

The convergence of robotics and nanotechnology opens up a wide range of career opportunities for industrial engineering graduates. Potential career paths include:

- Robotics Engineer: Design, develop, and implement robotic systems for various industrial applications.

- Nanotechnology Engineer: Focus on the development and application of nanomaterials and nanoscale devices in manufacturing processes.

- Industrial Systems Engineer: Optimize production systems by integrating advanced technologies such as robotics and nanotechnology to improve efficiency and productivity.

- Quality Control Engineer: Utilize nanosensors and robotics to enhance quality assurance processes in manufacturing.

- Research and Development Engineer: Conduct cutting-edge research to develop new applications and innovations at the intersection of robotics and nanotechnology.

Industry Demand and Job Prospects

The demand for skilled professionals in this field is on the rise, driven by the ongoing advancements in technology and the need for more efficient and sustainable industrial processes. Companies across various sectors, including manufacturing, aerospace, automotive, and healthcare, are seeking engineers with expertise in robotics and nanotechnology. As a result, graduates with an industrial engineering degree and specialized knowledge in these areas can expect strong job prospects and competitive salaries.

Conclusion

The future of robotics in industrial engineering, driven by the advancements in nanotechnology, holds immense potential for revolutionizing the industry. From enhancing material engineering properties and precision to enabling smart manufacturing and improving energy efficiency, the integration of these cutting-edge technologies promises to transform various sectors. As we have seen, understanding what is industrial engineering and the impact of these advancements is crucial for both current professionals and aspiring engineers.